PPS filter felt

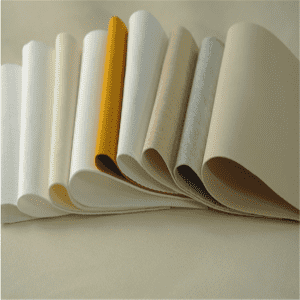

Polypropylene filter felt

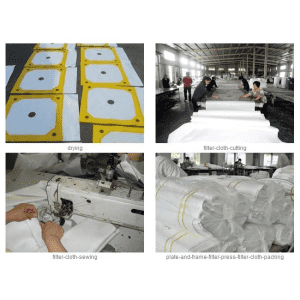

Our company produces high-quality polypropylene fiber to make polypropylene needle filter felt. Besides the advantages of ordinary needle-punched filter felt, polypropylene has better acid resistance, alkalinity and lower softening point than polyester fiber, so polypropylene needle felt is generally used in flue gas temperature below 100℃ and high acid and alkalinity, or in liquid-solid separation field with higher acid and alkalinity.In the field of liquid-solid separation, polypropylene needle filter felt is usually used with plate-frame filter press, vacuum filter suction machine, belt filter, centrifugal filter and other liquid-solid separation equipment. It not only has the characteristics of good dimensional stability, high strength and low elongation,Because of its smooth surface, porosity and high permeability, it also has the unique advantages of low vacuum resistance, energy saving and easy cleaning. In mineral processing, coal preparation, petroleum, chemical industry and other industries, the need to filter small particles and ensure fine filtration occasions, polypropylene needle filter felt is far superior to the traditional woven filter material performance.

Polypropylene fiber needle-punched filter felt is usually made of 3 d or 6 d polypropylene short fiber, and reinforced base cloth is woven with high strength silk.

polypropylene needle-punched filter felt is mainly used in the field of liquid-solid separation in metallurgy, mining, petroleum, chemical, chemical fiber, medicine, food and other industries.

Polypropylene filter felt technical data:

|

Fiber |

polypropylene fiber |

polypropylene fiber |

polypropylene fiber |

|

|

scrim |

polypropylene filament |

polypropylene filament |

polypropylene filament |

|

|

weight |

500g/m2 |

550g/m2 |

600g/m2 |

|

|

thickness |

2.0mm |

2.1mm |

2.2mm |

|

|

Breaking intensity |

warp(N) |

900 |

950 |

1050 |

|

weft(N) |

1100 |

1200 |

1300 |

|

|

breaking elongation |

warp(%) |

≤25 |

≤25 |

≤25 |

|

weft(%) |

≤40 |

≤40 |

≤40 |

|

|

air permeability(m3/㎡·min) |

15 |

13 |

11 |

|

|

90℃ Thermal shrinkage warp |

< 1% |

< 1% |

< 1% |

|

|

90℃ Thermal shrinkage weft |

< 1% |

< 1% |

< 1% |

|

|

working temperature |

90deg ℃ |

90deg ℃ |

90deg ℃ |

|

|

acid-resisting |

excellent |

excellent |

excellent |

|

|

alkali-resisting |

excellent |

excellent |

excellent |

|

|

Finish treatment |

Heating, singeing, calendering |

|||